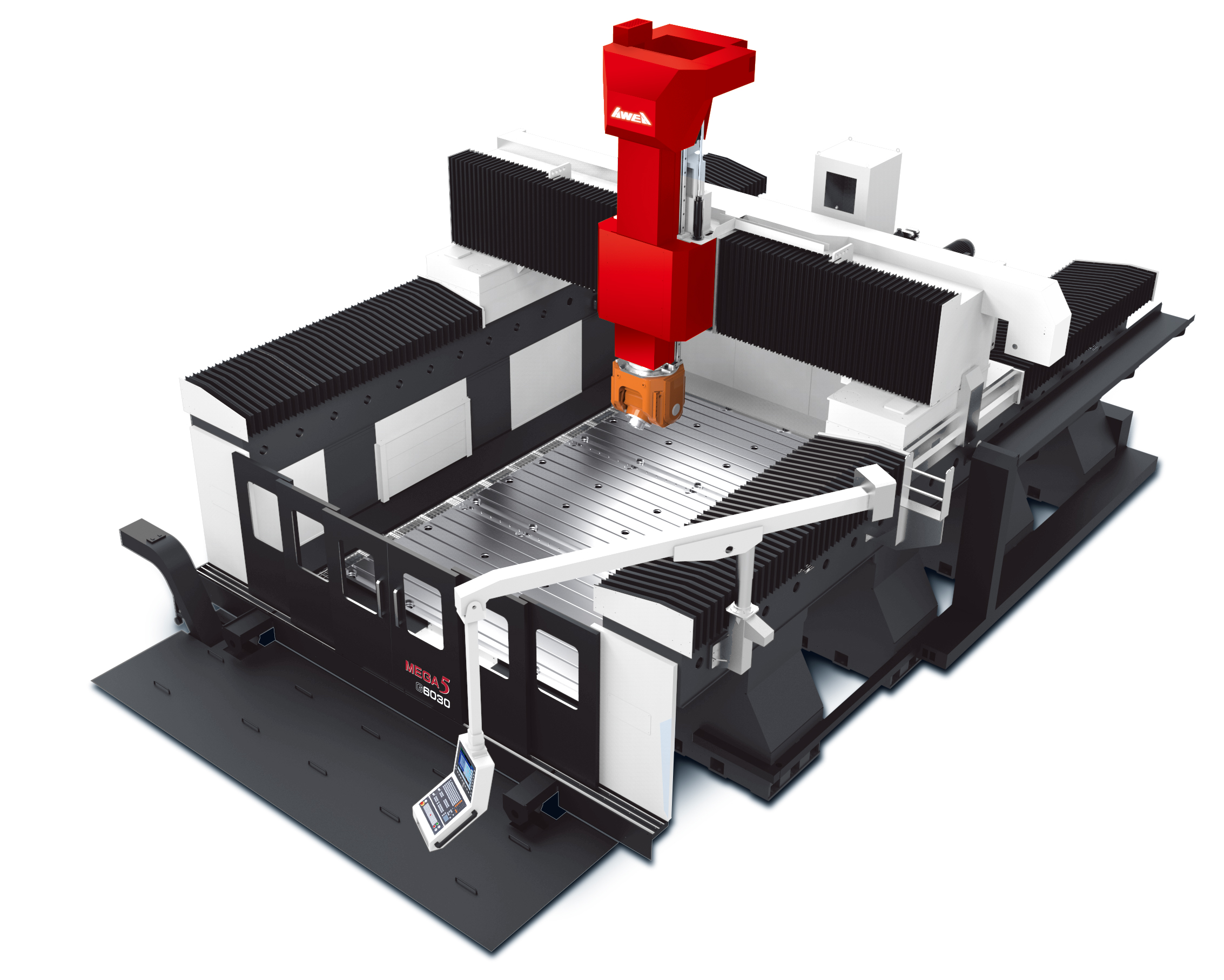

The AWEA MEGA5 G10047

Maximum Performance 5-Axes Machining Center

AWEA decades experience in bridge type machining center machine building and technology development combined with worldwide leading five axes head created the brand new MEGA5 series five axes bridge type machining centers. MEGA5 series are equipped with X, Y, Z, B, C five axes simultaneous movement control; vertical, horizontal machining and even intricate shape parts machining can be easily completed in one set up. Thus greatly increases the cutting capability and efficiency of large parts to cope with machining requirements in all kinds of industry.

Both HSK-A100 12,000 rpm high torque heavy duty spindle and HSK-A63 24,000 rpm high speed spindle are available for heavy cutting or fine finishing. Fixed columns or gantry type solutions are available for selection based on work piece size or weight. Comprehensive cutting solutions provide you best solution for upgrading capability required for high value added products.